At the heart of refrigeration systems lies the fan delay defrost termination switch, an indispensable component that orchestrates the defrost cycle, ensuring optimal performance and efficiency. Join us as we delve into the intricate workings of this essential switch, exploring its purpose, operation, troubleshooting, maintenance, and diverse applications across industries.

The fan delay defrost termination switch plays a pivotal role in the defrost cycle, initiating a sequence of events that effectively remove frost and ice buildup from the evaporator coils. Its precise operation ensures proper system functioning, preventing potential malfunctions and maintaining desired cooling temperatures.

Fan Delay Defrost Termination Switch Overview

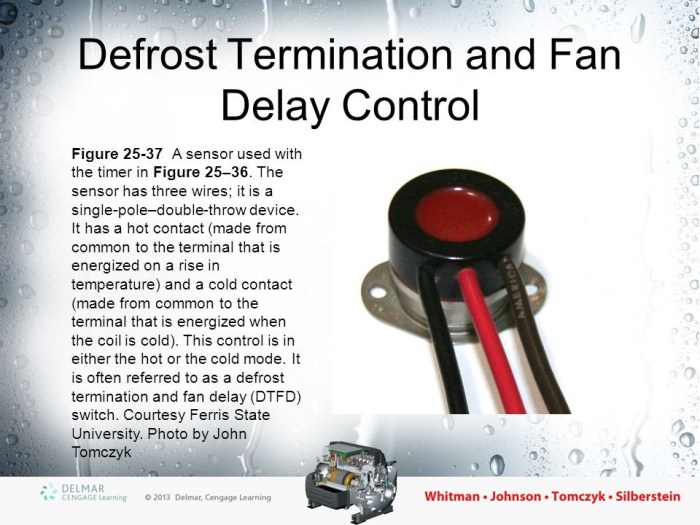

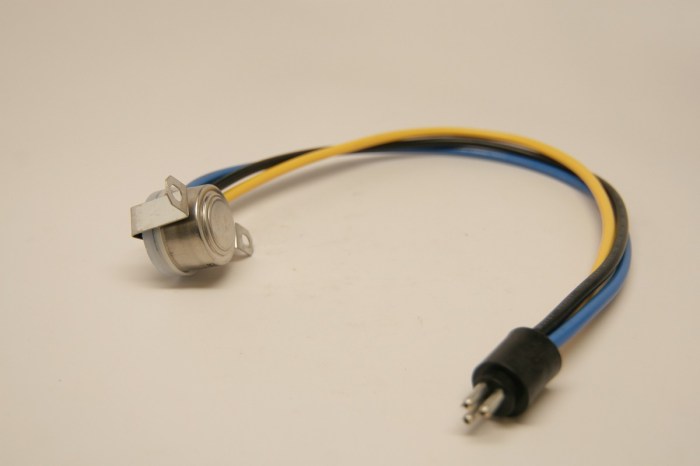

A fan delay defrost termination switch is a critical component in refrigeration systems that utilize a defrost cycle. Its primary function is to terminate the defrost cycle and restore normal refrigeration operation once the evaporator coil has been adequately defrosted.The

fan delay defrost termination switch is typically located in close proximity to the evaporator coil, mounted either on the coil itself or within the refrigeration unit. Its installation involves connecting it to the electrical circuit that controls the defrost cycle, allowing it to monitor the temperature of the evaporator coil and trigger the termination of the defrost cycle when the desired temperature is reached.

Typical Location and Installation Process

The fan delay defrost termination switch is typically installed on the evaporator coil or within the refrigeration unit. Its location allows it to accurately monitor the temperature of the evaporator coil and initiate the termination of the defrost cycle when the coil has been adequately defrosted.The

installation process of a fan delay defrost termination switch involves connecting it to the electrical circuit that controls the defrost cycle. This connection enables the switch to receive power and send signals to the defrost timer, which in turn controls the duration of the defrost cycle.

Fan Delay Defrost Termination Switch Operation

The fan delay defrost termination switch plays a critical role in controlling the defrost cycle of refrigeration systems. When activated, it initiates a sequence of events that ultimately terminate the defrost process.

The switch is typically located in the evaporator section of the refrigeration system and is connected to the defrost timer. When the defrost timer initiates the defrost cycle, it sends a signal to the fan delay defrost termination switch.

Defrost Cycle Stages and Switch Involvement

The defrost cycle consists of several stages, each of which is controlled by the fan delay defrost termination switch:

| Stage | Switch Involvement |

|---|---|

| Defrost Initiation | The switch is activated, initiating the defrost process. |

| Defrost Heating | The switch remains activated, allowing the defrost heater to operate and melt the ice on the evaporator coils. |

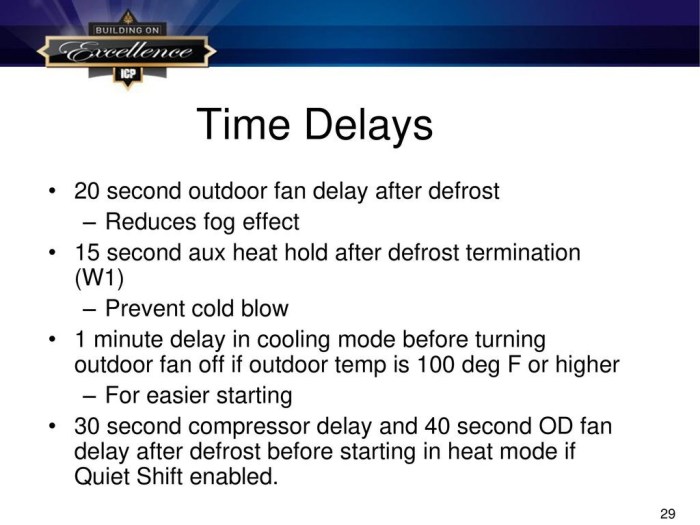

| Fan Delay | After a predetermined time delay, the switch deactivates, stopping the defrost heater and initiating the fan delay period. |

| Fan Operation | The switch remains deactivated, allowing the fan to operate and circulate air over the evaporator coils to remove any remaining moisture. |

| Defrost Termination | Once the fan delay period has elapsed, the switch reactivates, terminating the defrost cycle and returning the system to normal operation. |

Fan Delay Defrost Termination Switch Troubleshooting

Identifying and resolving malfunctions in fan delay defrost termination switches is crucial for maintaining optimal system performance. Common issues associated with these switches include:

- Switch failure

- Wiring problems

- Sensor malfunctions

Troubleshooting Guide, Fan delay defrost termination switch

To diagnose and resolve switch malfunctions, follow these steps:

1. Inspect the switch

Check for physical damage, loose connections, or corrosion.

2. Test the switch

Use a multimeter to measure continuity across the switch terminals. A faulty switch will show no continuity.

3. Check the wiring

Inspect the wiring for loose connections, breaks, or shorts.

4. Examine the sensor

Verify that the sensor is properly connected and is providing accurate temperature readings.

Fan Delay Defrost Termination Switch Maintenance

Regular maintenance of fan delay defrost termination switches is crucial to ensure optimal performance and extend their lifespan. Proper maintenance practices involve regular inspections, cleaning, and scheduled replacements.

Inspection and Cleaning

- Inspect the switch regularly for any visible damage, such as cracks, loose connections, or corrosion.

- Clean the switch terminals and contacts using a non-abrasive cleaner to remove any dirt or debris that may interfere with electrical conductivity.

- Ensure the switch is properly mounted and securely fastened to prevent vibration or movement that could affect its operation.

Replacement Schedule

The replacement schedule for fan delay defrost termination switches varies depending on the specific application and operating conditions. However, as a general guideline, it is recommended to replace the switch every 5-7 years to ensure reliable operation and prevent premature failure.

Fan Delay Defrost Termination Switch Applications

Fan delay defrost termination switches find applications in various industries, particularly in refrigeration and cooling systems. These switches play a crucial role in controlling the defrost cycle, ensuring optimal performance and energy efficiency.

Specific applications include:

Refrigeration and Air Conditioning Systems

- Terminating the defrost cycle when the evaporator coil reaches a predetermined temperature, preventing excessive defrosting.

- Delaying the fan startup after defrost to allow for proper drainage of condensate.

- Ensuring efficient defrost termination, reducing energy consumption and improving system reliability.

Industrial Refrigeration

- Controlling defrost cycles in large-scale refrigeration systems, such as those used in food processing and cold storage facilities.

- Preventing ice buildup on evaporator coils, maintaining optimal cooling performance.

- Reducing maintenance costs by extending the lifespan of refrigeration equipment.

Transportation Refrigeration

- Terminating defrost cycles in refrigerated trucks and trailers, ensuring the safe transportation of perishable goods.

- Preventing evaporator coil damage caused by excessive defrosting.

- Maintaining proper temperature control within the refrigerated space.

Commercial Food Service

- Controlling defrost cycles in commercial refrigerators, freezers, and ice machines.

- Ensuring food safety by preventing bacterial growth due to improper defrosting.

- Improving energy efficiency and reducing operating costs.

FAQ Section

What is the primary function of a fan delay defrost termination switch?

The fan delay defrost termination switch initiates and controls the defrost cycle, ensuring the removal of frost and ice buildup from evaporator coils.

How does the fan delay defrost termination switch operate?

When activated, the switch triggers a sequence of events that stop the fan and compressor, allowing the evaporator coils to warm up and melt the accumulated frost.

What are some common issues associated with fan delay defrost termination switches?

Common issues include switch malfunctions due to electrical faults, mechanical wear, or ice buildup, leading to improper defrost cycles.

How can I troubleshoot a malfunctioning fan delay defrost termination switch?

Troubleshooting involves checking for continuity, voltage supply, and switch operation, and replacing the switch if necessary.

What is the recommended maintenance schedule for fan delay defrost termination switches?

Regular inspections, cleaning, and periodic replacement as per manufacturer guidelines ensure optimal switch performance and prevent premature failures.